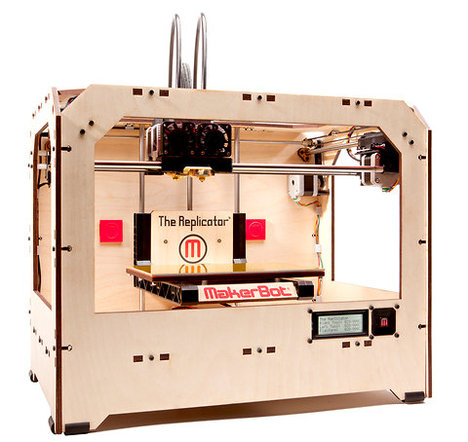

The Replicator 3-D printer. Source of photo: online version of the NYT article quoted and cited below.

The Replicator 3-D printer. Source of photo: online version of the NYT article quoted and cited below.

Back in 2005 technology “visionary” Neil Gershenfeld predicted the soon to be seen day when personal fabricators would follow the path of computers which progressed from mainframes costing millions to mini-computers costing hundreds of thousands to personal computers costing a couple of thousand. Well apparently that day is here.

Now we will see if the implications are as far-reaching as Gershenfeld predicted.

(p. B7) By now you may have heard about the Replicator, a $1,750 3-D printer made by the Brooklyn start-up MakerBot, due next month. If not, the significance of the Replicator is that it is the first 3-D printer to break the $2,000 barrier. Here’s more about what the Replicator can and can’t do.

Q. What does a 3-D printer use?

A: Spools of coiled A.B.S. (acrylonitrile butadiene styrene) plastic that costs about $45 each per kilogram. This is the same materials that is used to make Lego blocks. It is strong, safe and comes in many colors. One spool can make about 176 chess pieces.

For the full story, see:

WARREN BUCKLEITNER. “Gadgetwise; A 3-D Printer for Under $2,000: What Can It Do?” The New York Times (Thurs., January 26, 2012): B7.

(Note: bold in original.)

(Note: the online version of the article was dated January 23, 2012, and had the title “3-D Printing for the Masses: MakerBot’s Replicator.” The online version differs in several places from the print version. Where they differ, I quote the print version.)

The Gershenfeld book discussed above is:

Gershenfeld, Neil. Fab: The Coming Revolution on Your Desktop–from Personal Computers to Personal Fabrication. New York: Basic Books, 2005.