"From left, Bob Weiss of the X Prize Foundation; Larry Page of Google; Peter Diamandis of X Prize; Buzz Aldrin, the astronaut." Source of caption and photo: online version of the NYT article quoted and cited below.

"From left, Bob Weiss of the X Prize Foundation; Larry Page of Google; Peter Diamandis of X Prize; Buzz Aldrin, the astronaut." Source of caption and photo: online version of the NYT article quoted and cited below.

(p. 33) THE quests are monumental: end global warming; build a private spaceship; cure diseases; develop a car that can go 100 miles on a gallon of gas.

But the prizes are also monumental: millions and millions of dollars.

Such extreme public interest projects have been taken up by foundations, most prominently the X Prize Foundation, an 11-year-old group in Santa Monica, Calif., that rewards innovation on an entirely new scale.

“The world faces difficult problems — bigger than government, business and nonprofits can handle,” said Tom Vander Ark, president of the X Prize Foundation. The foundation encourages entrepreneurship, he said, and “competitions can create and reshape markets.”

In 1996, the foundation offered a $10 million prize, called the Ansari X, for someone to invent a private passenger rocket ship able to fly nearly 70 miles up and back again. A team led by the aerospace engineer Burt Rutan, and paid for with more than $20 million from Paul G. Allen, a founder of Microsoft, collected the $10 million in 2004.

The X Prize Foundation is not alone in its ambitious ventures: Google.org, the nearly two-year-old philanthropic arm of Google, has kicked off a $10 million competition to inspire production of plug-in hybrid vehicles so energy efficient they can sell excess electricity back to the utility.

. . .

“It’s a new kind of grant-making,” said Jonathan Greenblatt, an entrepreneur who sold his company, Ethos Water, to Starbucks and became a senior adviser to the X Prize Foundation. “It’s a mode that encourages experimentation rather than prescribing solutions. It sets the stage for innovation and dynamism that the grantor can’t anticipate.”

. . .

Cash prizes to induce innovation are not new. Peter Diamandis, the 46-year-old aeronautical engineer and physician who founded the X Prize Foundation, said he was inspired by the $25,000 aviation prize offered in 1919 by a New York hotelier, Raymond Orteig, to the first person to fly nonstop from New York to Paris. The prize went, of course, to Charles Lindbergh, whose grandson, Erik Lindbergh, is on the X Prize Foundation board.

In the same spirit, “We asked ourselves, how do we demonstrate the technology and stimulate market interest?” said Dan Reicher, director of climate and energy initiatives at Google.org. “How do we advance the technology around plug-ins? The usual way is to quietly go about looking at investment opportunities, make investments and have some impact. We decided to take a different route, a public request for investment proposals. We wanted to look beyond the usual players, bring attention to a critical area and catalyze competition and innovation.”

. . .

The X Prize Foundation announced the new competitions at the Clinton Global Initiative, a conference organized by former President Bill Clinton and held in September in New York.

“Think of this,” Mr. Clinton said at the time. “Twelve prizes in areas designed to break barriers to human health, have children live longer, solve all these education problems and do it in the most cost-effective way. This is the most amazing idea to me, trying to unleash entrepreneurship in the public interest.”

For the full story, see:

(Note: ellipses added.)

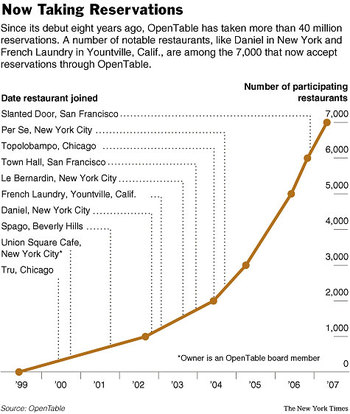

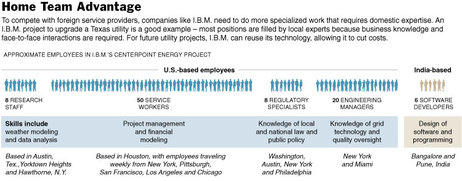

Source of graph: online version of the WSJ article cited below.

Source of graph: online version of the WSJ article cited below.  CEO of Linear Technology Corp. Source of image: online version of the WSJ article cited above.

CEO of Linear Technology Corp. Source of image: online version of the WSJ article cited above.

Source of graph: online version of the WSJ article cited below.

Source of graph: online version of the WSJ article cited below. Motorola CEO. Source of image: online version of the WSJ article cited above.

Motorola CEO. Source of image: online version of the WSJ article cited above.

(Note: ellipses added.)

(Note: ellipses added.)

In the photo immediately above, Don and Andrea Steirle work in their lab. The map to the left shows the location of the Berkeley Pit. Source of the photo and map: online version of the NYT article quoted and cited above.

In the photo immediately above, Don and Andrea Steirle work in their lab. The map to the left shows the location of the Berkeley Pit. Source of the photo and map: online version of the NYT article quoted and cited above.